Typisch JOHNE,

wie man es auch dreht und wendet …

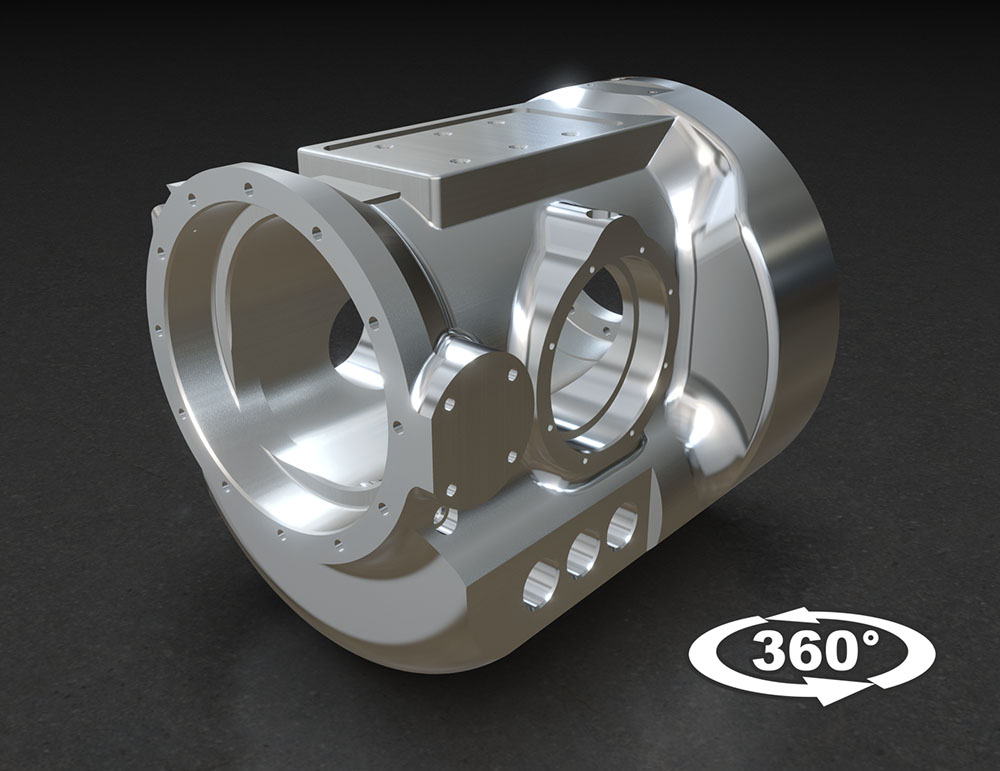

Wenn sich eines unserer Produkte – gleichgültig ob aus Werkzeug- oder Komponentenfertigung – von seiner besten Seiten zeigen soll, dann präsentiert es sich im günstigsten Fall im Rundum-Blick!

Machen Sie sich selbst ein Bild mit dieser interaktiven 3D-Visualisierung eines Getriebegehäuses – als Beispiel für die Bearbeitung von hochwertig legierten Edelstählen mit JOHNE-Sonderwerkzeugen sowie mit weiteren Vollbohr-, Aufbohr- und Feinbohrwerkzeugen.

Klicken Sie in das Motiv und dann in das sich öffnende Fenster. Drehen und wenden Sie das Gehäuse wie sie wollen. Sichtbare Präzision und Qualität sind das Ergebnis – und wenn Sie es (sich) auf den Kopf stellen …